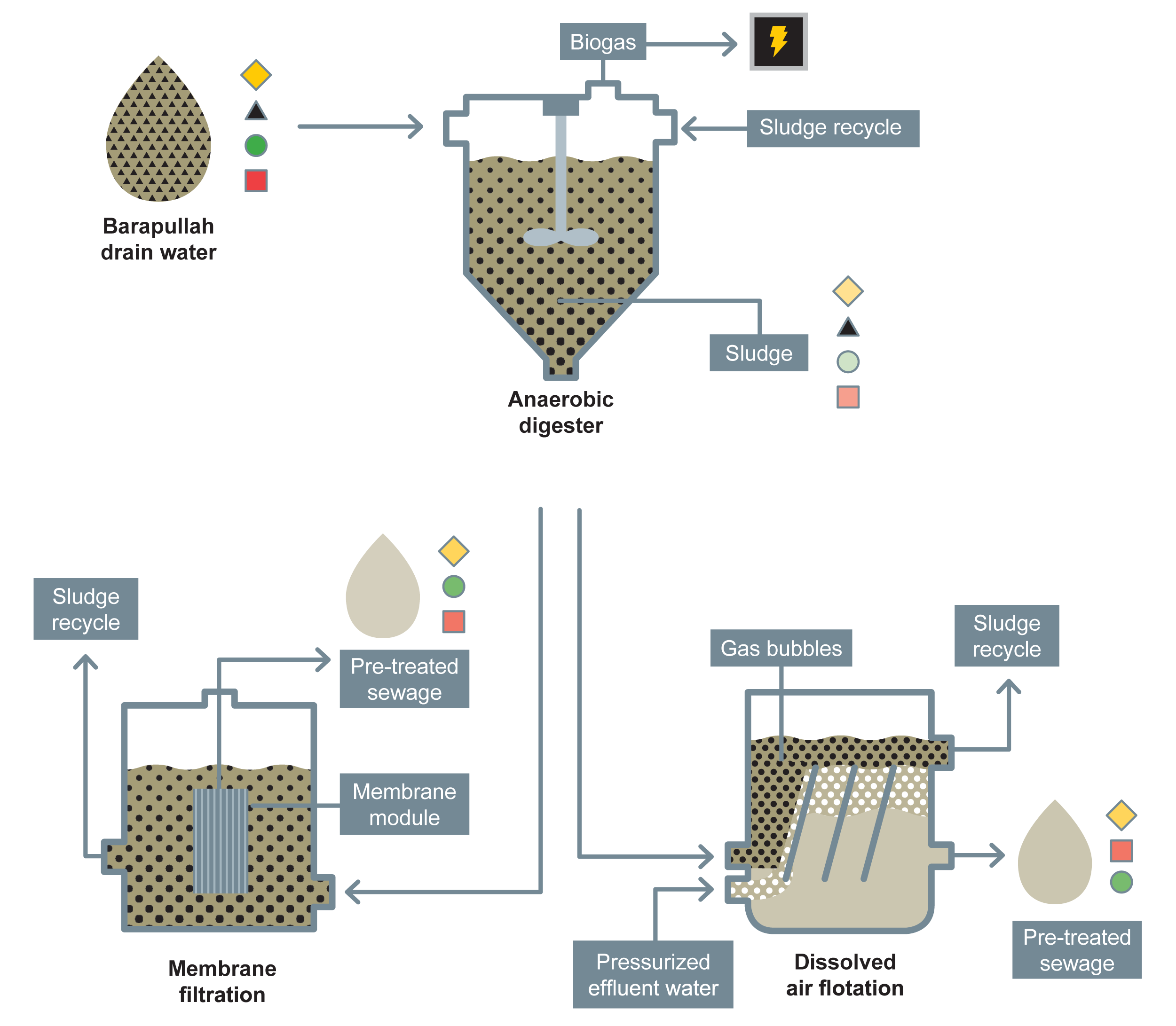

For reliable water reuse, organic material has to be removed from the wastewater. Our aim is to develop a stable and robust process for the removal of organic material and its conversion into biogas. This system will ensure superior effluent quality which is suitable for additional treatment. Anaerobic treatment would be used. Solids separation from the treated wastewater will be done either by membrane filtration (as part of Anaerobic Membrane Bio Reactor (AnMBR) technology) or by dissolved air flotation (DAF).

For the removal of organic material, the basis is formed by anaerobic technology. In these systems bacteria grow on in the absence of oxygen and break down the organic material from the incoming wastewater and convert parts of it into biogas. By filtering the bacterial slurry, or sludge using the membrane modules, the slurry can be separated from the water. The anaerobic system can also be combined with dissolved air flotation (DAF) technology. This system uses gas bubbles to separate water and particles. Particles stick to the bubbles and rise up, effectively separating them from the now clear water.

The anaerobic treatment produces sludge and biogas. Both these products can be used as resources. The energy in and heat from biogas can be recovered with high efficiency using solid oxide fuel cells (SOFC). The sludge can be utilised to manufacture activated carbon and as a partial replacement for clay in bricks and tiles suitable for construction purposes.

Several solutions are being developed to cost-effectively uncouple water flows from the flow of the in water suspended solids. The solutions aim for a similar effluent quality as conventional industrial AnMBRs.

In this work, the anaerobic membrane bio reactor (AnMBR) integrates flat-sheet ceramic microfiltration membranes with an anaerobic reactor. The membrane module can effectively filter the bacterial slurry from the water phase. The membrane modules are made from compressed and sintered ash that is generated in local sugar factories by combustion of waste sugarcane bagasse (solid residue from pressed sugarcane).

Membrane properties such as porosity, pore size distribution and surface characteristics can be adjusted. This allows for the development of membranes with high throughput, high quality filtered water and high resistance to fouling. Especially membrane fouling prevention is an important factor as this could lead to high operating cost. Testing is being carried out at the pilot site using real Barapullah water.

Similarly we are developing a novel integrated anaerobic digestion dissolved gas flotation system that will improve the hydraulic operation under high fluctuations in flow rate, while not compromising on particulate free effluent. The basis is formed by dissolved air flotation (DAF) technology.

DAF technology uses pressurized clean water, that under atmospheric conditions form fine air bubbles. The air bubbles rise up through the incoming wastewater. The particles in the water stick to the air bubbles and rise up resulting in efficient separation of particles and water. The air bubbles contains oxygen which is toxic to anaerobic bacteria. For this reason initial research will also focus on the effect of oxygen on the anaerobic systems. Another option is to use the produced biogas itself as the carrier gas.

Resource recovery

By reusing the co-produced biogas and bacterial slurry, sludge, added value is created which helps with the overall economics and social acceptability of the pre-treatment system.

Biogas

To effectively use the biogas produced in anaerobic systems, solid oxide fuel cells (SOFC) are used. Through integrating anaerobic and SOFC technology, direct injection of biogas becomes a possibility. Before injection, the biogas has to be purified from pollutants such as hydrogen sulphide (H2S), siloxanes and other volatile organic compounds. SOFCs have an improved electric conversion efficiency compared to conventional gas turbines, as the heat that is generated can also be utilised.

Sludge based materials

The sludge can be used as a partial substitute for clay in the production of construction material such as bricks and tiles. The sludge and conventional clay based raw materials can be mixed in different ratios and prepared by moulding and firing. The material properties will be tested and compared to conventional products. Another aspect is the preparation of activated carbons from sludge. Carbons are used as adsorption material in various industries including water treatment. The properties of the carbon will be characterized in detail and their potential applications will be studied.

Technology behind project 3a

Technology behind project 3a